Pad-Mount Transformers for Utility

Pad-Mount Transformers for Utility

Pad-mounted transformers are distribution transformers ground-mounted on a concrete pad that service underground power networks. These unites step down the distribution voltage to the secondary voltage for residential, commercials, and industrial loads. Because they are fully enclosed, quiet, weatherproof, and tamperproof, padmounts are the preferred choice for installation in public areas. Our pad-mounted transformers are available in single-phase, three-phase, and grounding (zig-zag) configurations.

Primary drivers for growth for pad-mount transformers in the utility market include:

- Expansion of rural and urban residential communities.

- Growing investment in upgrade of aging utility infrastructure and transmission & distribution networks.

- Need for safe, low sound, compact, reliable distribution transformers in public access areas.

- High efficiency, DOE guidelines.

- Growth in digital infrastructure with harmonic loading.

Virginia Transformer is a market leader in power transformer manufacturing since 1971. Our leadership in design and manufacturing experience for pad-mount transformer applications for public power and municipal utilities includes special considerations for:

- Operating in harsh outdoor environments.

- Tamperproof design with kirk-key interlock and padlock provisions for public safety.

- Live- or dead-front construction; loop feed or radial feed.

- Designed to meet system harmonic profile.

- Overvoltage and overcurrent protection.

- Saturation and power factor.

Virginia Transformer is the largest U.S.-owned transformer manufacturer in North America. Our custom-engineered units are designed with a 60-year lifespan and delivered with the shortest lead times in the industry.

STANDARD FEATURES

- Commercial, residential, and industrial applications

- Dead-front or live-front configuration

- Loop or radial feed applications

- Rating: up to 10 MVA

- High voltage: up to 35 kV delta or wye connected

- BIL: 200 kV

- Step-up or step-down operation

- Aluminum or copper windings

- Fluid: mineral oil or FR3 biodegradable oil

- Temperature rise: 55º, 65º, or 75º

- Design construction: 3-legged stacked core

- Design mitigates heating, gassing, and partial discharge

OPTIONAL FEATURES

- Electrostatic shielding

- Fluid: environmentally friendly or high-flashpoint Envirotemp™ FR3™

- Designed to maximize efficiency (extreme low loss)

- Customized impedance to match system short circuit requirements

- Temperature rise: 55º, 65º, or 75º

- Infrared window

- External mounted weak-link fuse box for quick replacement

- Current-limiting fuses

- Load-break switch (2 and 4 position)

- Rad valves for ease of replacement

- Circuit breakers

- Stainless steel construction

- CSA, IEC, UL

ABOUT US

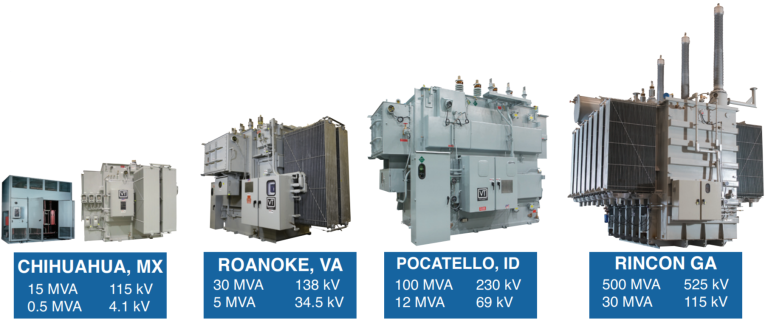

Virginia Transformer – Georgia Transformer is a US-based Corporation that has been in business for over 60 years with 6 plants in North America designing and manufacturing a full line of power transformers from 500 kVA to 500 MVA, and up to 500 kV class.

Our Value Proposition: We promise to supply the most “resilient” power transformer designed for 60 years of life, that will meet the 24/7/365 resilient power needs of the customer.

Our value proposition is based on three key process philosophies:

• Robust Design: Developed by expert engineers with over 300 years of electrical design experience using proprietary digital design tools, verified by off-the-shelf arsenal of digital simulation tools and executed with efficient proven processes.

• Flawless Execution: Based on 3T pillars of training, technology, and transformer manufacturing processes.

• Continuous Monitoring of Transformers: Using VCM technology supported by a 24/7 full-fledged service organization.

Virginia – Georgia Transformer takes pride in being a Minority Business Enterprise – equipped with newer technology, state-of-the-art equipment, highly qualified and experienced engineers, and overall improved processes – which allows us to provide the most reliable products, and the shortest lead times in the industry.

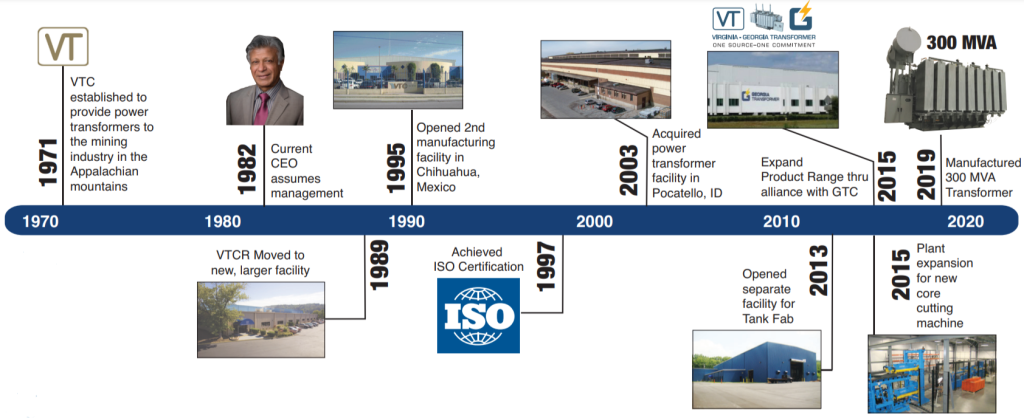

OUR HISTORY