Transforming Energy for America

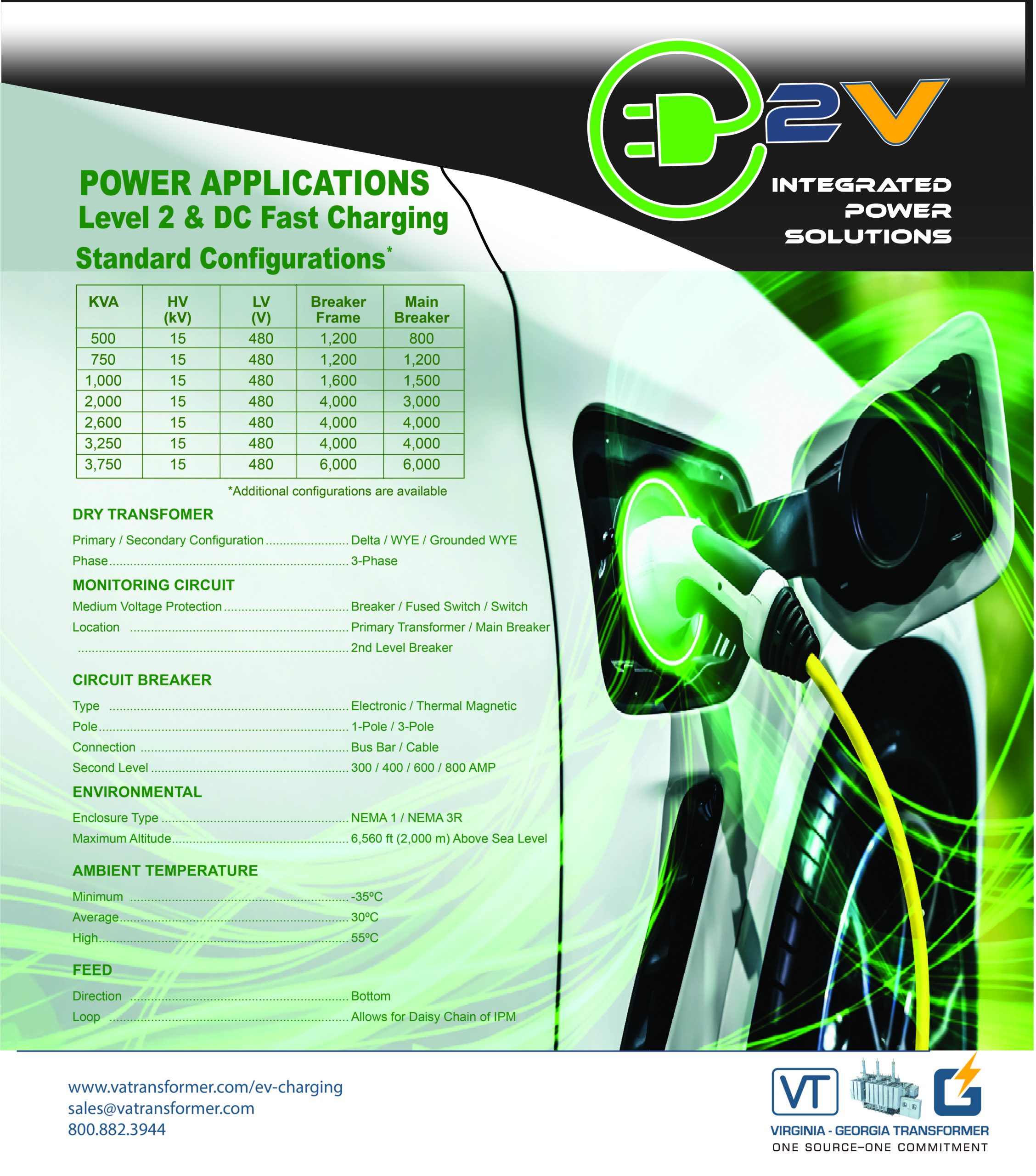

EV Charging

Benefits of the Integrated Power Module

PLUG & PLAY

E2V is a self-contained power module moves power seamlessly from substation to EV rectifiers and chargers. The all-in-one convenient package that includes

- Medium Voltage Switchgear

- Dry Transformer

- Main Breaker Panel

- Low Voltage Power Distribution

FAST START-UP

NEMA 3R rated and designed to withstand operating environment ranging from -35°C to 55°C, place E2V on a concrete pad, connect and flip the switch. E2V all-in-one convenient package is wired to the power grid and moves power seamlessly from substation to EV rectifiers and chargers.