Transforming Energy for America

Tank Fabrication and Paint

Tank integrity is essential for reliability and durability. VTC designs all transformer tanks to meet our high quality standards and specific customer specifications.

Advanced 3-dimensional computer-aided design tools are used to create drawings for review to ensure:

- Mechanical integrity for operation and shipping

- Ability to withstand full vacuum and pressure during operation

- Mitigation of leaks

- Withstand seismic events if required

- Minimization of damage if an internal fault occurs

Important features of our transformer tanks include:

- A36 hot-rolled, low-carbon steel plates are cut per engineering drawings using a plasma machine

- Welded top cover with lifting eyes for top only, slanted top cover is provided if required

- Provision on base for skidding

- Transformer lift lugs and jack pads for jacking, pulling, and lifting

- No-corner welds with tank seams welded inside and out provided per specification / requirement

- Tank seams are welded using a robot welding setup

- Tanks are designed for inert gas preservation

- Raised flange design with machined gasket grooves

- Manhole provided for easy access during maintenance and service

- Tank wall braces provided to withstand full vacuum and pressure during operation

Substrate: Hot-rolled, low-carbon, A36 plate steel.

Surface Preparation: Interior surfaces of the tank and cover are thoroughly cleaned and prepared prior to the application of the white, two-part, oil-resistant epoxy enamel.

Coating Procedure: Interior surfaces of the tank and tank cover are coated with white, two-part, oil-resistant epoxy enamel. Exterior surfaces are primed with a two-part epoxy primer and top-coated using two-part urethane high-gloss finish coat.

All coating materials are applied with air-assisted spray guns, with the paint delivered to the guns using plural component equipment that automatically measures and mixes the paint systems to eliminate operator error.

Coatings then “sit” to produce a uniform cured coating.

Coating Result: Interior coating compatible with transformer oil per ASTM 3455 and a 3-mil exterior coating capable of meeting ANSI C57.12.28.

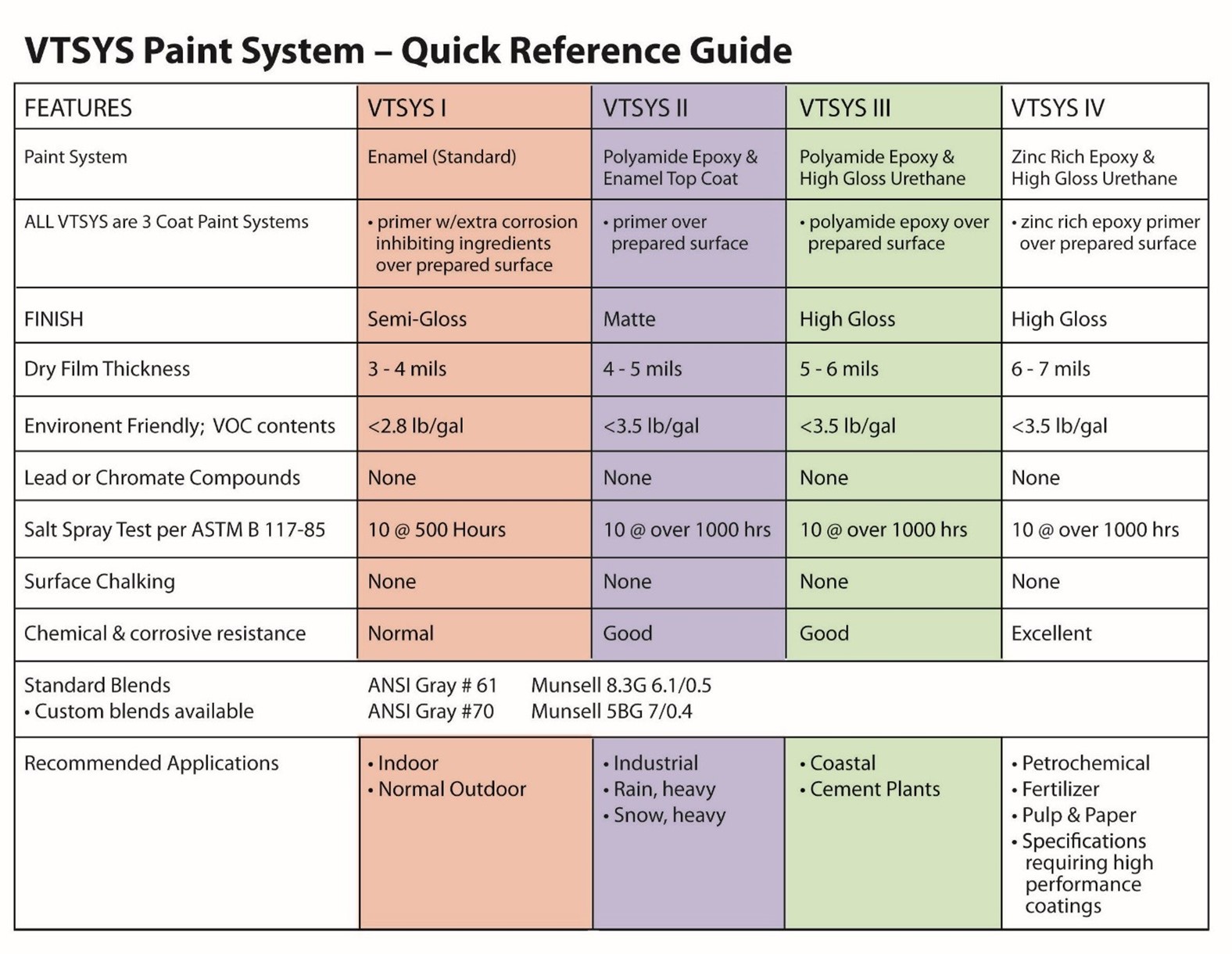

For over 50 years, our transformers have excelled in a variety of locations, from indoor to outdoor and in the harshest environments. Our six plants offer the flexibility to exceed protection for just about any site conditions and customer requirements. If you have a special paint requirement for your power transformer, contact us. We will work with you to find the best paint solution for your transformer(s).