Transforming Energy for America

Quality First

At Virginia Transformer Corp., we place the utmost attention to quality and customer satisfaction in all phases of engineering and manufacturing. Our quality assurance programs are applied to all our processes from the time the order of the transformer is made, through engineering and manufacturing to shipping and to the final customer handshake after field installation has been completed.

To ensure diligent application of our quality standards we created the “VA Way” Five Star Quality System:

“VA Way” Five Star Quality System

- Knowledgeable and dedicated leadership with a “quality-first” mindset

- Critical to Quality (CTQ) control plans, design standards, and shop operating procedures developed from over 50 years of experience

- Training, auditing, and skill certification program to assure product reliability and craftsmanship

- Experienced technical leaders in all areas of manufacturing

- Final quality assurance program to achieve customer satisfaction at all stages of project execution from order receipt to transformer installation on the pad

Engineering Quality Assurance

- Review customer order and design a control plan for each order

- Design validation plan with failure mode effect analysis (FMEA) for new designs, new components, and new technology

- Engineering Process Audit (EPA) and inspection plan for engineering process assurance

Vendor Quality Assurance

- Detailed quality control plan for incoming material inspection

- New component evaluation and testing plan

- New vendor evaluation program

- Vendor performance score card

- Vendor quality surveillance audits and vendor rating system

Process Assurance in Manufacturing

- Training and skill certification programs for operators

- Statistical Process Controls (SPC) for processes to manufacturing

- A three-tier quality control plan for process adherence to assure product quality

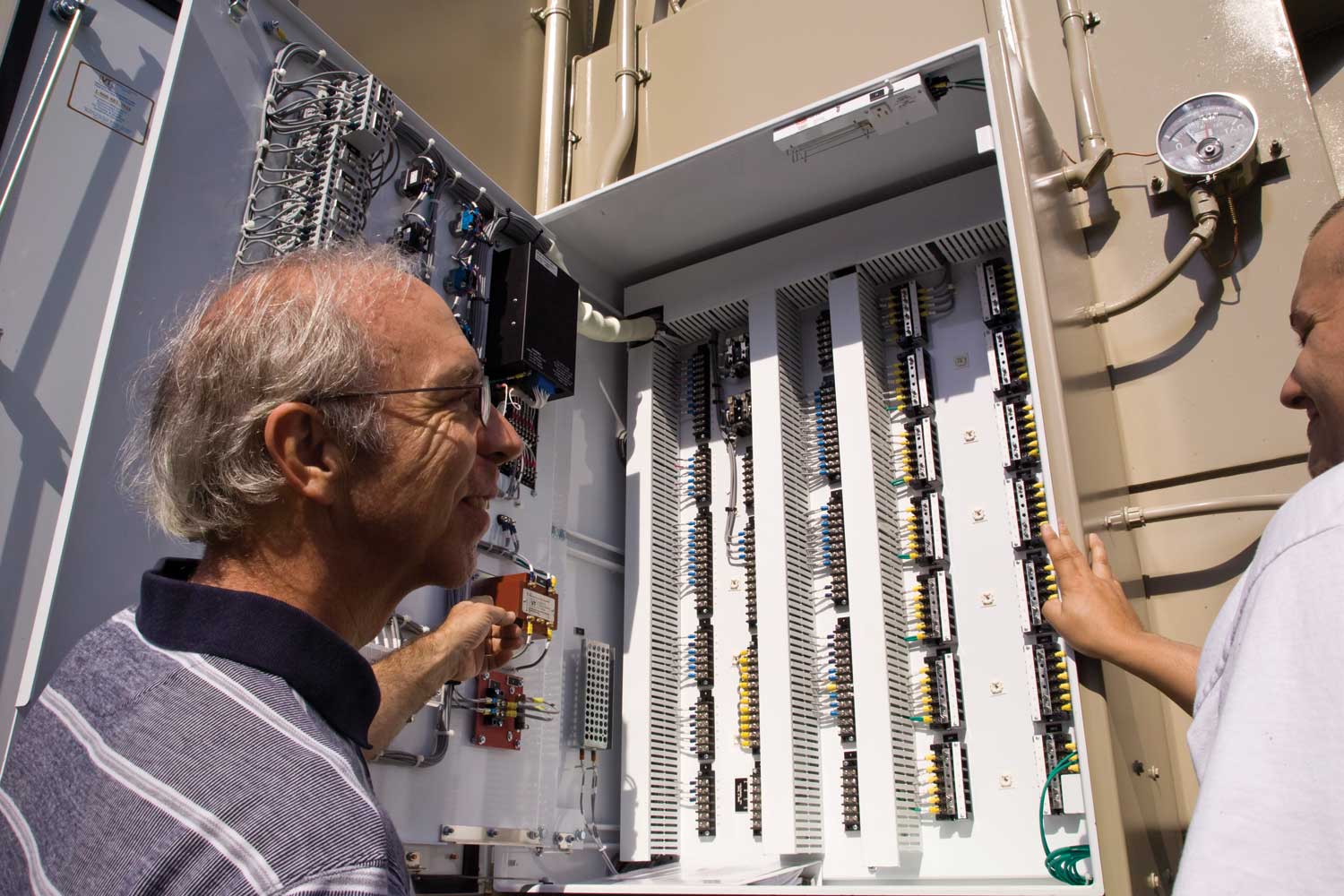

Final Quality Assurance

- Transformer tests per ANSI/CSA standards/customer specification requirements

- “Fit, form, function” verification and customer specification compliance

- Shipment, tracking, and delivery coordination with customer

- Installation, oil processing, and field testing

- Customer feedback surveys to assure overall service quality and experience

Employee Training

We stay current with the industry standards in training and certifying our employees, and we have a comprehensive training program across the entire organization.

Employee Training Programs

- Resources providing extensive knowledge in design and electrical testing based on industry standards

- Mechanical Engineering training for Electrical Designers

Operators Training Programs

- “BAT” (Build A Transformer) training program

- “Hands on” essential skills and special processes training

Certifications

ISO-9001 certification- All facilities are ISO-9001 certified

UL Listings

- Includes liquid-filled units up to 69 kV class

- Dry-type units 35 kV, 150 BIL

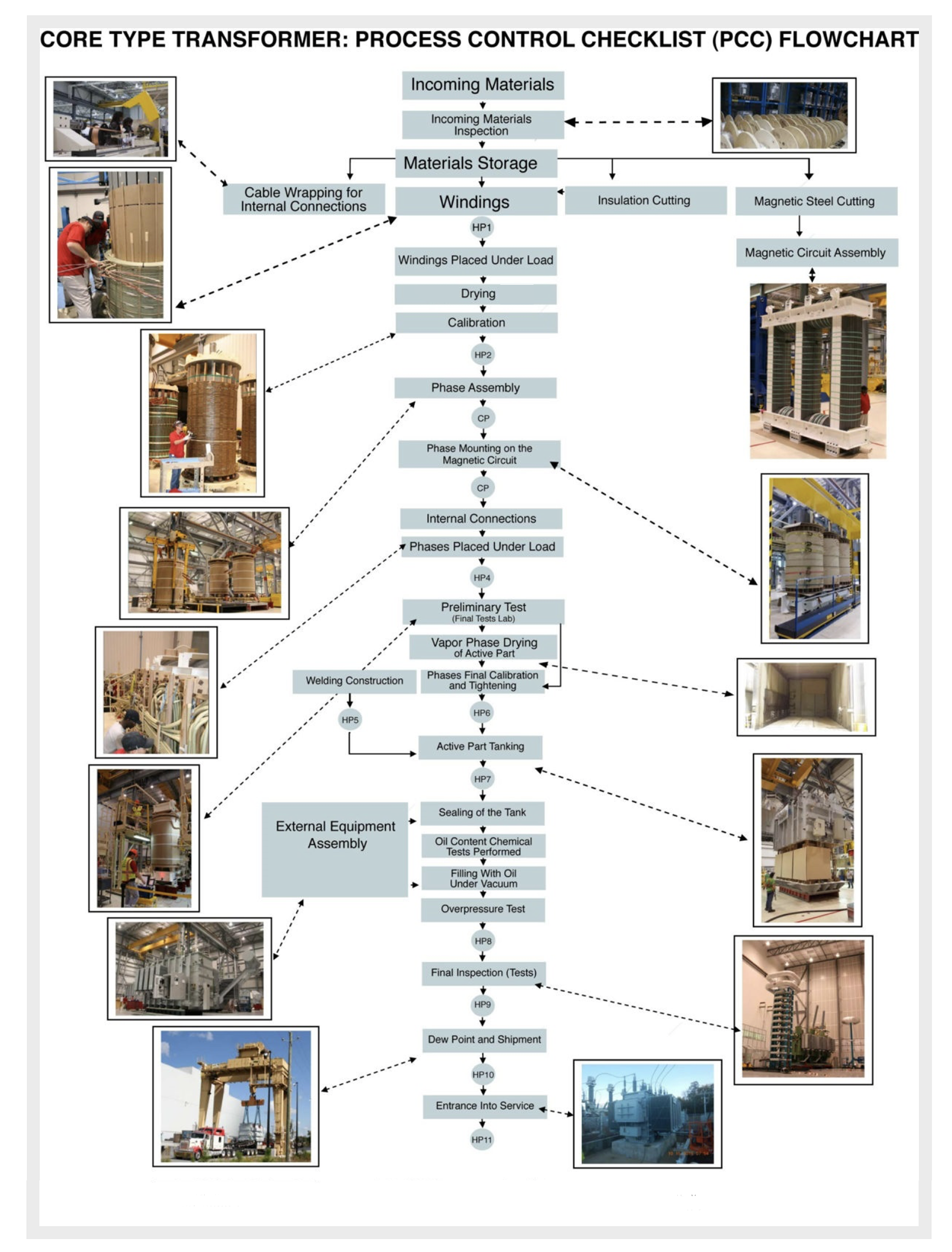

Process Flow Chart